Tag Archive for: Engineered

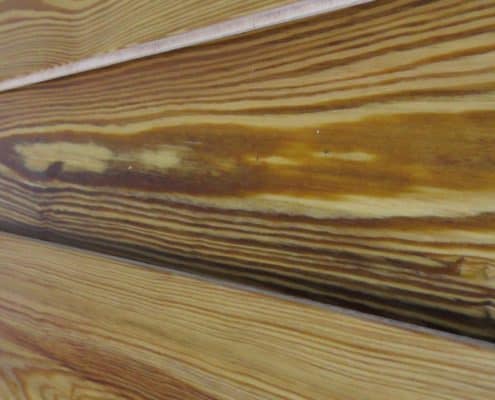

Take a look at this gorgeous Precision Engineered Heart Pine wood flooring that just came off of our finish line. It is coated with Diamond 7, a proprietary finish developed by Heritage Wood Finish Company specifically for Goodwin’s River-Recovered® wood.

Goodwin’s Precision Engineered Heart Pine wood flooring is handcrafted using the same high quality heart pine as our solid wood lines. And, unlike inferior engineered flooring products, ours has thick wear layers so it can be sanded over and over again. These wear layers also help the floor remain flat in changing humidity.

Let’s take a look at some other interesting facts that solidify Goodwin’s position as the industry gold standard in engineered wood flooring:

- Goodwin was the first reclaimed wood company in America to produce an engineered floor in the U.S.A

- We use sustainable River-Recovered and reclaimed wood to produce our precision engineered wood flooring products

- Safe for kids and pets – Goodwin uses low formaldehyde glues and a certified “green” back

- Manufactured in long lengths to look like solid wood

- Lifetime structural warranty on the floor

- 20 year warranty on the finish

Looking to remodel your home or office in the upcoming year? Goodwin’s Precision Engineered wood flooring experts are ready to help. Give us a call today!

This vintage beach home on Florida’s First Coast is being remodeled and incorporates a variety of Goodwin woods to achieve a unique, modern look. Still under renovation, this home in sunny Ponte Vedra, Florida (near Jacksonville) is taking on a distinctive style all its own.

Once complete, the home will feature 2360sf of Goodwin’s Vintage Precision Engineered (building reclaimed) heart pine ceilings and floors. This is the first time that we know of where an engineered product is being incorporated into a ceiling. It looks absolutely gorgeous!

The custom crafted contemporary stair rail, stairs and treads are Legacy (building reclaimed) solid heart pine. Legacy heart pine was also used for the upstairs hall shelves. All Legacy wood was then stained a beautiful, deep, rich chocolate color.

Finally, the River-Recovered® Heart Cypress Character used on the vaulted ceiling contrasts nicely with the light gray painted walls.

We love sharing sneak peeks of building and remodeling projects in progress. We look forward to posting stunning photos of this newly remodeled beach home once complete.

Most people have seen wild black cherry hardwood flooring at one time or another, but did you know that the species is perfect for wood feature walls and accents, too? Take a look at this beautiful office showroom for Avalon Park West community in Wesley Chapel, Florida. Our good friend Chris Webb at CWebb Designs in Tampa crafted the interior using Goodwin’s wild black cherry. JNT Interiors was the designer on the project.

Wild black cherry wood floors have a history of being especially popular because of the arching grain patterns and slight mineral coloring. These same unique features are also what makes is so desirable for wood feature walls, wood ceilings and accents. Goodwin sustainably harvests this species and mills it into our exclusive wild black cherry engineered flooring, solid flooring, wood feature walls and wood ceilings. Contact us today to find out how wild black cherry can add depth and warmth to your home or office!

Goodwin rescues trees which have fallen during storms and/or are scheduled to be cut down due to development. We work closely with foresters and land planners to sustainably harvest this beautiful wood to ensure it is not doomed to waste. One of the species we rescue is wild black cherry.

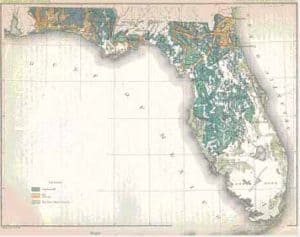

Wild black cherry primarily grows in the eastern half of North America and Mexico. Goodwin mills sustainably harvested wild black cherry logs into our solid wood flooring and engineered wood flooring. Some argue wild black cherry is more desirable than standard cherry because it often develops arching and/or burled grain patterns, along with slight mineral colors for added beauty. Wild black cherry’s natural coloration varies from deep pink to rich red brown tones.

This short but informative video shows Dan Petersen of Heritage Wood Finish Company pre-finishing a solid wild black cherry wood floor with a low sheen diamond 7 finish for one of our valued clients:

Our friends at The Sustainable Design Group in Gainesville, Florida are the architects for the remodeling of a home in Cedar Keys where the wild black cherry solid wood flooring you see in the video will be installed.

Interested in a wild black cherry solid wood floor or engineered wood floor? If so, please give us a shout so we can custom craft a sustainably harvested wood floor just for you.

Local. Growing up in a tourist destination, I often heard this word. It was a defense people used or a title they adopted to identify themselves with their city. Being a local seemed to give people a sense of self. Today, I more typically hear the word local used to express the quality or integrity of a product, rather than a person.

Not too long ago, everything was local and distinguishing a product as such would have seemed redundant. But now, with just a few taps on our smartphones, we have access to almost any product worldwide. Because of this, I find myself buying specific products online so I can read reviews and compare features to ensure I am getting the best. But, when I do this, I am sacrificing locality for quality. What if we didn’t have to make this choice? What if I could have quality products, personalized to my needs, knowing they were still produced sustainably and locally?

Let’s take a look at Goodwin Company. They manufacture a high quality product available globally, but sourced and manufactured locally.

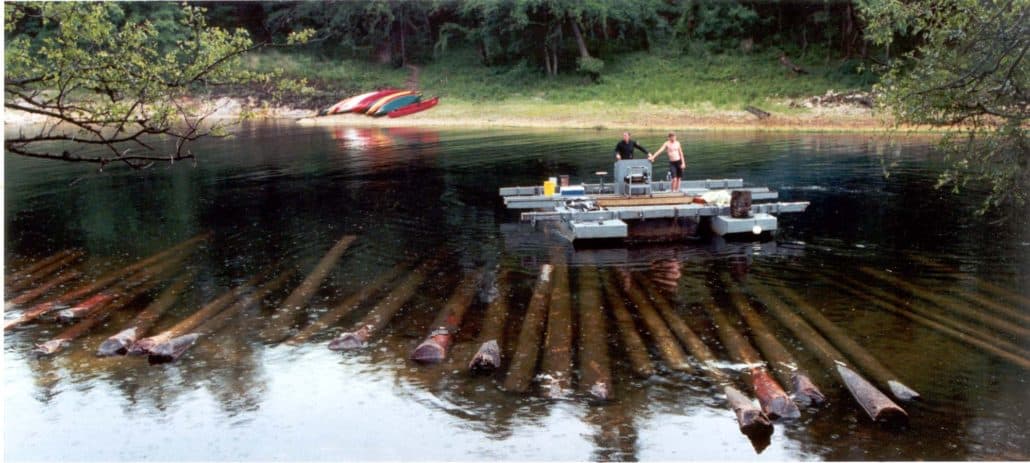

Quality- Goodwin offers 100% old growth heart wood that is harvested in compliance with the Florida Deadhead Logging Permit to ensure protection of ecosystems.

Personalized-The Heritage Wood Finish Company, in partnership with Goodwin, specializes in finishes for heart wood. Their finishes are second in hardness only to diamonds and are available in an array of colors. All finishes have low to no VOCs and are safe for children and pets.

Sustainable- Wood is sourced from 19th century industrial buildings, storm damaged trees, and sustainably harvested forests. Sawmill shavings are sold to be used in Biomass plants and the company is looking for ways to implement a solar sawmill as well as wind energy.

…………………………………………….

Lauren Corley is a guest author for Goodwin and is a senior in the Innovation Academy at the University of Florida studying Sustainability in the Built Environment with a minor in Innovation. She began her involvement with Goodwin at the 2015 Greenbuild conference in Washington D.C. She is from the Panhandle of Florida and gained an interest for sustainability and its use in space as a high school student. Since moving to Gainesville she has interned for the Repurpose Project as well as the Alachua County Public Schools under the Energy Conservation Specialist.

On A Factory Finished Wood Floor That Is…

Here is an article by Andrew St. James, Goodwin’s Technical Consultant:

After years of observing the performance of factory-finished wood floors, the micro-bevel has emerged as the standard side profile for prefinished flooring. Some building owners prefer the look of square-edge flooring, but it is more difficult to achieve good results with square-edge prefinished wood floors.

Installation of a square edge factory finished floor demands better Jobsite conditions in addition to more skill and care in the installation process. If a square edge is raised slightly higher than the adjacent board not only is there a visual problem, the potential for later damage is increased. Here are some suggestions to help improve your outcome if you choose a square edge factory finished floor:

- The subfloor must be precisely flat to assure the alignment of adjacent boards. This requires more care to achieve variation less than 3/16” out in 10 feet or 1/8” in a 6-foot radius that is normally allowed.

- Nailing must be precise and with even pressure to avoid exposed square edges. The elastic nature of wood allows deflection if some boards are pulled down too much (or too little) when nailing. When nails are not set evenly the result can be similar to that seen with subfloor irregularities.

- Minor seasonal cupping caused by the growth ring structure is normal in solid wood. Boards change the size and shape slightly. This slight movement is more noticeable in a square-edge factory finished product.

Goodwin’s micro-bevel starts at twenty-thousandths of an inch and is less after sanding and finishing. The tongue and groove help maintain the alignment of the board ends. This stabilizing effect combined with the better strength properties of the end grain of the boards minimizes the need to bevel the ends.

Please send us your feedback on this short summary of Pros and Cons on To Bevel or Not To Bevel!

Beveled Edge

Pros

- Can be very slight

- Minimizes noticeability of misalignment

- Normal subfloor variance within industry standards is allowed

Cons

- The concern of dust in the groove

- Slight line visible between the boards

Square Edge

- Suitable for an onsite finish

- Matches existing historic flooring

- Avoids a slight line between boards

- The subfloor requires more care to make a precisely flat

- More skill needed to nail precisely, with even pressure

- Any over/under increases the potential for finish failure

- Slight movement from seasonal changes is more noticeable

We received more feedback from our NWFA Certified Sales Professional class last week:

The tour of the facility was great, so many things to see and remember. It’s amazing how just a few (all of your staff there) can make such a difference of how we take care of surroundings around us! The class was fantastic, Roy was great. Very informative and down to earth presentation that anyone would and could follow, and understand.

Dave Short

Special Order Manager

Kimal Lumber & Hardware

You may remember this video of Matt Marwick, Precision Floorcrafters, using Goodwin’s antique heartpine log rounds to craft a floor at Kimal Lumber’s Sarasota location.

You can see many samples of Goodwin wood at Kimal, including engineered flooring, curly heartpine, cypress log rounds, cypress paneling, and pecky cypress. We value Kimal because they are one of the few independent lumber dealers in southwest Florida. They, like Goodwin, have a passion for providing high quality, sustainable products. And, they appreciate the beauty and value of sinker logs and old wood!

Their Event Center, located in Venice, Florida, was constructed using the latest Green Building practices. It serves as a “living model” of Green Building Concepts and Sustainable Building Practices, while providing space for special events for the industry and the community.

Goodwin is proud to call Kimal Lumber one of our valued partners!