“I am writing to offer my highest praise, and most profound gratitude to The Goodwin Company for their partnership on the creation of the floors of our new art museum. The beautiful floors of our 23,000 sq ft exhibition galleries were lovingly crafted of exquisite reclaimed heart pine, salvaged from the joists of the 1926 M. Leo Elliott designed former Sarasota High School.

As an art museum director and curator, meticulously designing every aspect of the gallery experience was paramount to the success of the project. After seeing the gorgeous raw lumber during the demo phase of the project, centuries-old, I became committed to repurposing this special wood—from an historic, aesthetic and environmental standpoint, this was unquestionably the right thing to do.

But it was not easy.

We were so fortunate to find our partners at The Goodwin Company to bring this ambitious project to fruition. The floors are beautiful in their own right, and they provide an elegant platform and framing device for the wide range of contemporary art we install there. They complement, but never compete with the art. We could not be more pleased with the results.

Goodwin understood the complexity involved in adaptive reuse, and the particular challenges involved in repurposing a 1920s era building into a high-performance building, with the necessary environmental conditions for an art museum, and the heavy foot traffic of a public space. During construction Goodwin brought the first technical director of the National Wood Floor Association to meet with the entire team and assist with the subfloor, sound attenuation and insulation requirements. Once the floor was installed, Goodwin brought the finish manufacturer’s team onsite to consult with the Museum’s curatorial and facilities team to ensure the long-term preservation of this fine art environment.

In addition to their consummate professionalism and technical expertise, the Goodwin team was a pure delight to work with, always going above and beyond to creatively problem-solve and to ensure the highest quality product possible.

If you are considering The Goodwin Company for your project, I would be delighted to share more about this journey, should you wish to discuss.

With best regards,

Anne-Marie Russell, Founding Executive Director, Sarasota Art Museum ”

Howard Brickman Teaching a Wood Flooring Inspection Class at Goodwin Company’s Micanopy, Florida Headquarters.

For over four decades, Goodwin has connected with many highly respected wood flooring professionals.

The article below on wood floor cupping is written by longtime Goodwin friend and colleague Howard Brickman. Howard was the first ever Technical Director of the National Wood Floor Association and he has taught several wood floor inspection classes at Goodwin.

Recently, Howard traveled to Bermuda to install 10,000 square feet of our River Recovered® Antique Heart Pine Flooring. Quite impressive as Bermuda has a climate that requires considerable expertise to install wood flooring at the correct moisture content and conditions!

Our connections with wood flooring professionals help ensure that your project is completed as smoothly as possible. We can connect you with highly respected industry experts and communicate with them over the course of your project.

Stuck on a wood flooring project… or looking to get started… Call Goodwin at 800-336-3118.

Solid wood, engineered wood, vinyl, luxury vinyl, laminate, bamboo, tile, carpet…there are now more flooring choices than ever before. And, there seems to be new flooring companies popping up every day in an effort to get a piece of this global, billion dollar industry. Goodwin employs an eco-friendly process to manufacturing our flooring that is safe for your family and pets. Our process takes extra time and careful oversight, but in the end, the health and safety of our valued customers comes first. The health benefits of our flooring speaks for itself:

- Hypo-Allergenic

- Low to Zero VOC Finishes

- No Formaldehyde

- Genuine Product Handcrafted from Nature

Read More About Health Benefits of Goodwin Flooring

For more than four decades, Goodwin Company has prided ourselves on providing the most beautiful and healthy wood flooring in the world….period. We never have and never will compromise on quality or stray away from our green and healthy manufacturing processes. If you are ready to give your home or office a new look in 2021, we can help. Give our antique wood specialists a call today!

Goodwin Company partnered with LAKE|FLATO architects in San Antonio, Texas to provide our River-Recovered® and reclaimed Heart Cypress for the construction of the Eleanor and Nicholas Chabraja Visitor’s Center at Naples Botanical Garden. The end result was gorgeous – so much so that it is among the 15 projects detailed in LAKE|FLATO Architects’ new book, Nature | Place | Craft | Restraint. If you liked what Goodwin did for the Naples Botanical Garden, you’ll definitely want to check out the other amazing projects in this new book!

River-Recovered and reclaimed wood is trending in 2021. If you have an upcoming remodeling, historic restoration or new construction project, our antique wood specialists can help select the perfect species to warm up your home or commercial space. Give us a call to learn more today.

- Learn More About Goodwin’s River-Recovered Heart Cypress

- See Our Specials on Existing Milled Inventory

Be sure to follow our new Daily Log on Twitter. It’s chock full of fun facts and interesting tidbits. We invite you to take a short break from the workday to see what news floats down the river!

A few years ago, Goodwin Company partnered with LAKE|FLATO architects in San Antonio, Texas to provide our River-Recovered® and reclaimed Heart Cypress for the construction of the Eleanor and Nicholas Chabraja Visitor’s Center at Naples Botanical Garden. We’re happy to announce that this is one of the 15 projects detailed in LAKE|FLATO Architects’ new book, Nature | Place | Craft | Restraint. If you liked what Goodwin did for the Naples Botanical Garden, you’ll definitely want to check out their other amazing projects in this new book!

Goodwin’s Legacy Heart Pine in particular is a popular species often specified for projects in coastal areas. This new “lodge-like” home on Florida’s East Coast was designed by Marcia Hendry of Urban Cracker Design. Goodwin provided 1800 square feet of 7″ Vintage Precision Engineered (PE) and Legacy Naily Heart Pine for the project. The Vintage PE was used for flooring, and the Naily Heart Pine for paneling and cabinetry. Take a look:

The rich color and character of Legacy Heart Pine complements the metal and brick to create a distinguished yet rugged appearance. White ceramic was used to lighten the space. The walnut countertops and monkey pod wood slab table were crafted by Dan Peterson of Heritage Wood Finishing Company.

Hendry stumbled upon Goodwin while she was searching for unusual wood species.

“[Everyone at Goodwin was] wonderful to work with and always supplied samples and superb knowledge. They’re awesome, and that’s an understatement! Local, been around for a long time, and know what they’re doing: that’s what I think separates Goodwin from the rest.”

Marcia Hendry, Urban Cracker Design

Photos courtesy of Kamaran Wilson

Goodwin Company Tapped to Transform Historic Wood Assets into

Modern Engineered Heart Pine Flooring

The new Sarasota Art Museum is a remarkable story of adaptive re-use and building material recycling. Housed in the old 1926 Sarasota High School building, it is a contemporary art museum in the Kunsthalle tradition and now a premier venue for revolving shows of contemporary art.

Goodwin Company, pioneers of River-Recovered® heart pine and heart cypress, was recruited to participate in this adaptive re-use project by general contractor, Willis-Smith. The focus was to transform the second and third floors of the high school building by remodeling the boxy classroom space into two open concept exhibition halls.

All of the heart pine joists from each floor were removed and replaced with steel joists. The design team envisioned recycling the beams and turning them into finished wood flooring. Willis-Smith contacted Goodwin and the rest is history.

Goodwin Company cleaned the beams of all foreign objects, re-sawed the material into 1×6 lamellas and then milled it into 23,000 square feet of Precision Engineered heart pine flooring. What resulted was a magnificent story of adaptive re-use and building material recycling.

“Goodwin Company is often specified for adaptive re-use projects because of our dedication to ensuring each and every piece of antique wood is carefully cleaned, sawn, and milled to the highest standards,” explains Carol Goodwin, President of Goodwin Company. “It was important to ensure this new modern space gave a nod to the heart pine that was so much a part of the building’s rich history.”

The old Sarasota High School is a three-story building designed by architect Leo Elliott in the neo-gothic tradition. Behind the Sarasota Art Museum sits the modern Sarasota High School designed in 1959 by architect Paul Rudolph. Architecturally, the two buildings stand in stark contrast to one another. Several years ago, the circa 1926 building came up for sale and was under the threat of demolition. Concerned parties influenced the Sarasota School Board to lease the building to the Ringling College of Art & Design to create the new Sarasota Art Museum.

Lawson Group Architects led the adaptive reuse of the buildings, and Terence Riley of Keenan/Riley is the design architect for the project. Sarasota Art Museum’s executive director, Anne-Marie Russell, played a significant design role as well.

Look for more photos of the complete project coming soon!

Hicks Koski Tower

Tom & Sherri Koski Gallery

Photography: Ryan Gamma

Artist: Sheila Hicks Questioning Column

Goodwin Precision Engineered Heart Pine

Renovation In-Process

Midnight Heart Cypress is an interesting antique wood with a distinct look and style. Take a look at these photos of a gorgeous Precision Engineered Midnight Heart Cypress floor in a home in Texas:

Photos Courtesy of Oldham Goodwin Group, LLC

The home was expertly constructed by Martin & Sims Development. Goodwin partnered with them to provide 1690 square feet of 7″ Precision Engineered River-Recovered® Midnight Heart Cypress with an oil finish for flooring and stair treads.

Midnight Heart Cypress is as unique as it is beautiful. Here are some of its architectural features and specifications:

- Available with arching grain patterns

- Shows light to dark chocolate tones

- No knots over 1-1/4”

- 100% heart

- 100% dense growth with up to eight growth rings per inch

- 690 on the Janka scale comparable to Douglas Fir (660)

Midnight Heart Cypress – which displays a range of cozy brown hues, varying from light to dark chocolates – is milled from the same antique logs as lighter Heart Cypress. Its rich textured look makes it perfect for floors, walls, stairs and ceilings.

Want to learn more about how to incorporate either solid or Precision Engineered Midnight Heart Cypress into your home or office? Give us a call today!

Precision Engineered wood flooring is crafted from the same wood used in our solid wood flooring options. Take a look at this familiar residential project that incorporates Goodwin’s Vintage Heart Pine Precision Engineered wood flooring throughout the home:

The original flooring was white tile. The homeowners wanted to update their home with a timeless look. Since the classic look of antique wood never goes out of style, Goodwin crafted the Vintage Heart Pine Precision Engineered wood flooring you see throughout this home from reclaimed heartpine beams.

Precision Engineered wood flooring is an attractive option because it is often more affordable than solid wood flooring and can be easily glued directly on to a concrete slab. While most engineered products cannot be sanded and refinished, Goodwin’s Precision Engineered wood flooring features a thick 4mm wear layer, allowing it to be refinished multiple times.

Would you like to learn more about how Goodwin’s Precision Engineered wood flooring can transform your home or office? If so, give our antique wood specialists a call today.

When should you select flooring for your new custom home? Ideally, this process will begin while your architect is designing your home. Too often, people wait until their home is under construction to begin seriously considering flooring options. This can lead to significant pitfalls. Below is a summary of the main reasons why wood flooring should be specified during the design process.

Flooring Affects Numerous Aspects of the Home

Certain aspects of a home are affected by the type and height of the proposed flooring. For instance, the baseboards for solid wood flooring need to be set differently than baseboards for an engineered product. Subfloor is also a consideration. Whether your home will be slab-on-grade and/or over a joist system defines whether you should use solid plank or engineered flooring. Knowing the exact flooring you plan to incorporate into your new home will help ensure various aspects of the construction process are smooth and seamless.

Lead Time for Production

Depending on the type of wood flooring you are considering the production lead time could be a major factor. It takes much more time to manufacture wood flooring from newly recovered logs than it does to custom craft a floor from on-hand inventory.

Acclimation

Wood flooring should not be installed immediately upon delivery as it needs to be properly acclimated before installation. Certain factors such as humidity, subflooring and change of season can affect acclimation time. You want to make sure your flooring is delivered to your home site in time for it to be properly acclimated to the room(s) where it will be installed.

If you are working with a building design professional to develop plans for a new custom home, be sure to connect with us during this process. Our wood flooring specialists will work alongside you and your design team to help select the best wood flooring to meet your needs. We’re here to help!

We are often asked if our antique flooring can be installed over concrete. The answer is, “YES!”

This modern farmhouse was designed using reclaimed post and beam construction, a style typical of old New England farmhouses. Interestingly, while the design is typical, the foundation is slab on grade which is not typical of New England. Therefore, the architect specified Goodwin’s engineered flooring to glue down, sand and finish on site. The final product was 1925sf of 7″ Vintage Precision Engineered (PE) flooring along with 32 Legacy™ (building reclaimed) heart pine stair treads.

Photos by Lee Mallett. Click the photo to see the project gallery.

Lee Mallett of Giltedge Builders in Etna, New Hampshire is the builder and Christopher Smith in Norwich, Vermont is the architect.

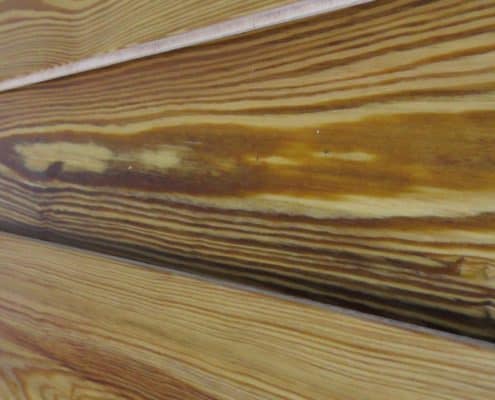

Take a look at this gorgeous Precision Engineered Heart Pine wood flooring that just came off of our finish line. It is coated with Diamond 7, a proprietary finish developed by Heritage Wood Finish Company specifically for Goodwin’s River-Recovered® wood.

Goodwin’s Precision Engineered Heart Pine wood flooring is handcrafted using the same high quality heart pine as our solid wood lines. And, unlike inferior engineered flooring products, ours has thick wear layers so it can be sanded over and over again. These wear layers also help the floor remain flat in changing humidity.

Let’s take a look at some other interesting facts that solidify Goodwin’s position as the industry gold standard in engineered wood flooring:

- Goodwin was the first reclaimed wood company in America to produce an engineered floor in the U.S.A

- We use sustainable River-Recovered and reclaimed wood to produce our precision engineered wood flooring products

- Safe for kids and pets – Goodwin uses low formaldehyde glues and a certified “green” back

- Manufactured in long lengths to look like solid wood

- Lifetime structural warranty on the floor

- 20 year warranty on the finish

Looking to remodel your home or office in the upcoming year? Goodwin’s Precision Engineered wood flooring experts are ready to help. Give us a call today!

More and more, today’s consumers are looking for local and sustainable options. Whether it’s locally grown produce from the neighborhood farmer’s market or recycled building products from the local architectural salvage company, today’s marketplace demands an alternative to inferior and poorly crafted imports. It should come as no surprise that discerning homeowners all over the country are seeking out similar products in the way of authentic, “Made in the U.S.A.” wood flooring.

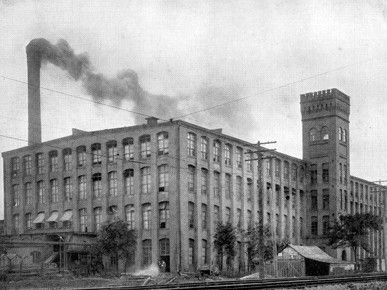

We thought you’d like to see the fascinating process that Goodwin Company goes through to bring clients the finest in reclaimed heart pine engineered flooring. In 2007, Goodwin became the first reclaimed wood company in the United States to manufacture an engineered floor here at home and not overseas. Goodwin offers its Precision Engineered product in both River-Recovered® and Legacy (building reclaimed) Heart Pine.

The following photos are very interesting and intriguing. They take you through the multi-stepped process of milling the highest quality flooring we know (even if it’s used as wainscoting like our clients did at the new Sea Scout base in Galveston, Tx.) From the reclamation of gigantic heart pine beams out of deconstructed 19th century industrial buildings to sawing and finishing the final product, Goodwin means quality. Goodwin means, “Made in America”.

Special thank you to Emily Burris and the ABC TV 20 (WCJB) team for featuring Goodwin Company for their “Made in America” series. Check it out: